Advantages of KBK Single Girder Aluminum Rail Crane

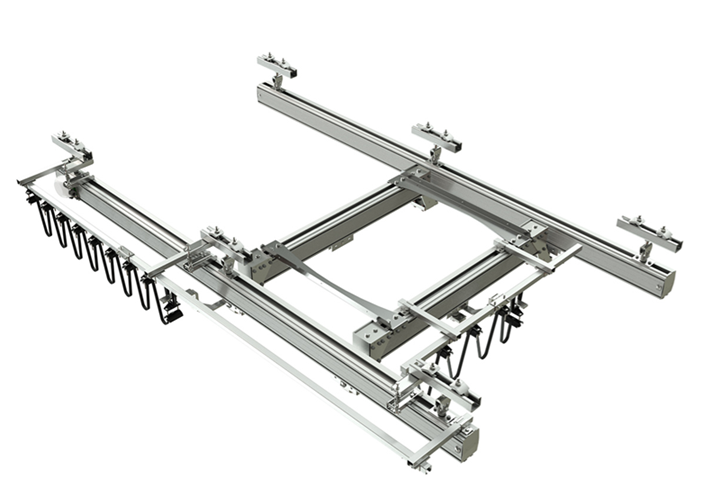

KBK single girder aluminum rail crane is a kind of light lifting equipment, usually composed of a track made of aluminum alloy, a spreader suspended on the track, an electric hoist and a control system. This kind of crane is lightweight, flexible, safe, reliable, efficient and energy-saving. It is a light lifting equipment suitable for various industrial sites and can improve work efficiency and ensure operational safety.

1. Compact structure and small space occupation

The design of the KBK single girder aluminum rail crane fully considers space utilization. Its compact structure allows it to minimize the floor space during installation. This is undoubtedly a huge advantage for production workshops with limited space. At the same time, its lightweight aluminum rail material also reduces the overall weight and reduces the pressure on the factory structure.

2. Smooth operation and high efficiency

The use of advanced drive and control systems enables precise positioning and rapid response. Its smooth running trajectory and efficient lifting capacity make the material handling process faster and smoother. This not only improves production efficiency, but also reduces the labor intensity of operators.

3. Safe, reliable and easy to maintain

The safety performance of KBK single girder aluminum rail crane is fully guaranteed. It is equipped with complete safety protection devices and fault self-diagnosis system, which can detect and deal with potential safety hazards at the first time. At the same time, its maintenance process is relatively simple, and standardized components and modular design make maintenance faster and more efficient.

4. Highly customizable and adaptable

KBK single girder aluminum rail cranes are highly customizable and can be customized according to different production needs and on-site environments. Whether it is lifting height, span or operating speed, it can be adjusted according to actual needs. This high degree of adaptability enables it to meet the material handling needs in various complex environments.

5. Energy conservation and environmental protection, low-carbon production

The needs of energy conservation and environmental protection are fully considered during the design and manufacturing process. The advanced drive system and energy-saving control technology it adopts greatly reduce energy consumption and reduce the company's operating costs. At the same time, the lightweight material of aluminum rails also reduces the burden on the environment and enables low-carbon production.

6. Easy to operate and highly intelligent

It is equipped with an advanced operating system and intelligent control module, making it easier for operators to operate and maintain. Through the intelligent control system, functions such as remote control, fault diagnosis and automated operations can be realized, further improving production efficiency and safety.

7. Low maintenance cost and long service life

KBK single girder aluminum rail cranes are designed to have a long service life and relatively low maintenance costs. Its high-quality materials and exquisite manufacturing technology ensure the stability and durability of the equipment, allowing companies to save a lot of maintenance costs during long-term use. At the same time, its standardized components and modular design also make the maintenance process easier and faster.