How to Choose Suitable Aluminum Cantilever Jib Crane

Aluminum cantilever jib crane is widely used in many industries for its lightness, high efficiency and corrosion resistance. Whether in electronic manufacturing, automobile assembly, food processing or biomedicine, this equipment can provide precise and efficient material handling solutions. However, when choosing an aluminum jib crane that suits your needs, you often need to consider many factors to ensure its efficiency and safety at work.

Clarify the operation requirements

The first step in choosing an aluminum cantilever jib crane is to clarify the specific operation requirements. Consider the following factors:

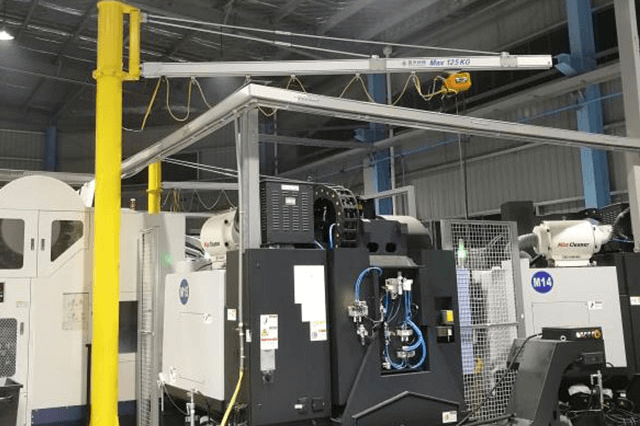

● Load capacity: Different models of aluminum jib crane can carry different weights, usually ranging from tens of kilograms to hundreds of kilograms. When choosing, you need to determine the appropriate load capacity according to the weight of the material being transported to avoid overloading.

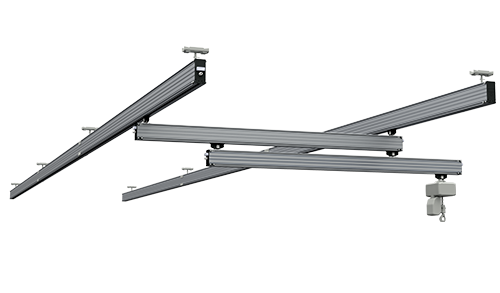

● Working radius: The length of the cantilever boom of the aluminum cantilever jib crane determines the operating range. You need to choose the appropriate boom length according to the spatial layout of the working environment to ensure that the required working area can be covered.

● Lifting height: Choose the appropriate lifting range according to the height requirements of the material being transported. Different working scenarios may require different lifting heights. When choosing, make sure that the lifting stroke of the crane can meet the actual working needs.

Consider the working environment

Aluminum cantilever jib crane is widely used in various working environments, but different environments have different requirements for equipment. The following factors need to be considered when choosing:

● Ambient temperature and humidity: If working in a high temperature or humid environment, the corrosion resistance and weather resistance of aluminum alloy are key, and the anti-oxidation ability of aluminum jib crane enables it to cope with such an environment. Especially in industries such as food and medicine, the corrosion resistance of equipment is crucial.

● Cleanliness requirements: If the equipment is installed in a clean room or dust-free environment, the impact of the equipment on air quality needs to be considered. Aluminum cantilever jib crane is an ideal choice in a clean room environment because of its smooth surface and low dust generation, which can ensure that the working environment will not be polluted.

● Space limitations: If the working area is limited, choosing a compact and height adjustable aluminum jib crane can save space and improve work efficiency to the greatest extent. At this time, the height of the column design and the extension range of the cantilever arm need to be flexibly selected according to the actual space on site.

Choose the drive mode

The drive mode of aluminum cantilever jib crane is divided into electric and manual. Different drive modes meet different usage requirements:

● Electric drive: suitable for places with heavy loads, frequent operations, and high efficiency and precision operation. Electric aluminum jib crane runs smoothly, has controllable speed, and can work stably for a long time. It is a common choice in industrial production.

● Manual drive: suitable for environments with light loads and low operating frequency. Manual operation is simple, economical, and has low maintenance costs. It is suitable for small workshops, assembly lines and other places.

Check safety and maintainability

Safety is one of the key factors when choosing an aluminum cantilever jib crane. Make sure the equipment is equipped with necessary safety devices, such as:

● Overload protection: prevent the equipment from overloading and protect the safety of the equipment and operators.

● Limit switch: prevent the equipment from running beyond the predetermined range to avoid damage to the equipment or cause safety accidents.

● Emergency stop device: in the event of an emergency, it can quickly stop the equipment to prevent accidents.

In addition, it is also very important to choose equipment that is easy to maintain on a daily basis. Aluminum jib cranes are usually simple in structure, easy to clean and inspect. When choosing, you should ensure that the equipment is easy to maintain, and that potential problems can be discovered and solved in time to ensure long-term stable operation of the equipment.

Choose the right supplier

It is crucial to choose an experienced and reputable aluminum jib crane supplier. A professional supplier can not only provide high-quality equipment, but also provide customized solutions according to your specific needs to ensure that the equipment can perform at its best in your working environment. With many years of manufacturing experience, KFCS CRANE can provide you with customized aluminum jib crane solutions and provide thoughtful pre-sales and after-sales services.

If you are looking for an efficient, safe and reliable aluminum cantilever jib crane, please contact KFCS CRANE. We will provide you with tailor-made solutions to help your production be more efficient and safe!