Characteristics of aluminum alloy rail crane

With the arrival of industry 4.0, we are pursuing the fourth industrial revolution led by intelligent manufacturing. Production and manufacturing can not be separated from the assistance of lifting equipment, and the factory has also moved from traditional manufacturing to a faster, newer and cleaner manufacturing environment. At this time, the aluminum alloy track can meet the requirements of these factories.

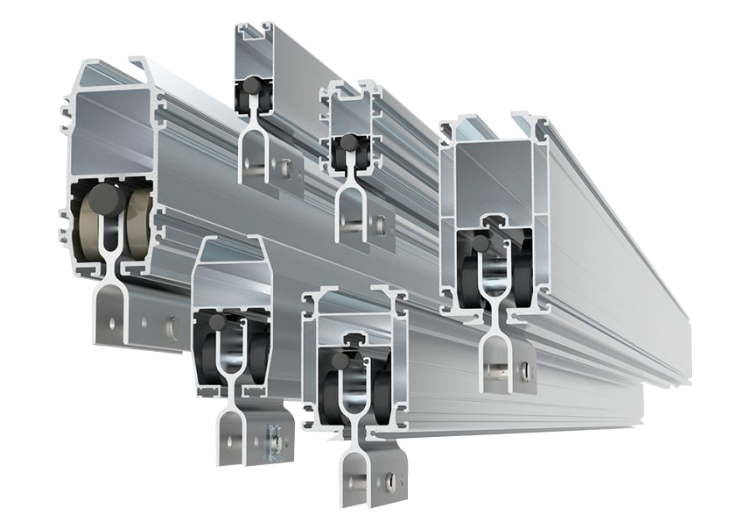

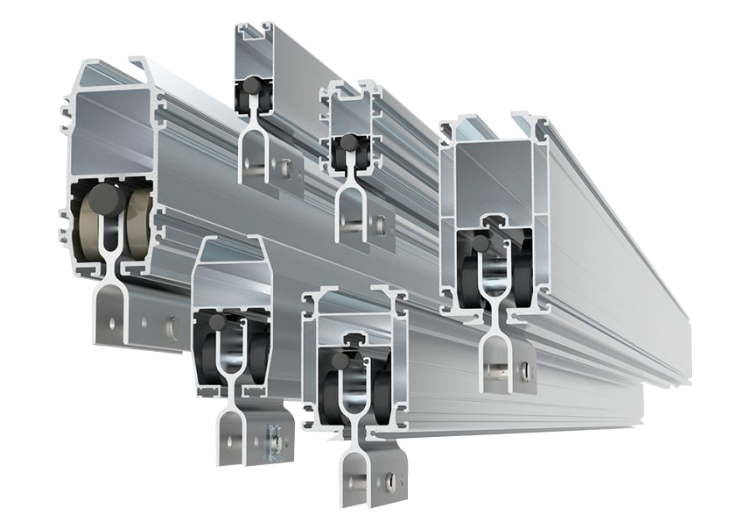

Aluminum alloy rail crane is a new type of light-duty lifting equipment which mainly applies aluminum alloy walking rails and pulleys, uses carbon steel as structural support or accessories, and combines aluminum alloy and carbon steel. The carrying capacity of aluminum alloy rail crane is from 125kg to 2000kg. The smooth and stable system makes your operation more convenient, more ergonomic, newer, better and smoother. Standard modular accessories make installation and transformation more convenient. The low friction coefficient makes it easier for the aluminum alloy rail crane to handle heavy loads. Nylon wheels and aluminum alloy surfaces are smoother. Standard modular accessories make installation and transformation more convenient. The low friction coefficient makes it easier for the aluminum alloy rail crane to handle heavy loads. Unique combination of nylon wheel and aluminum alloy surface. So that the distance between the lifting points can be larger and the cost can be saved. The ergonomic workstation design of the aluminum alloy rail crane has a direct impact on productivity, so that your production can benefit a lot. It redefines the smooth operation characteristics of the new light-duty crane system, making your lifting more easy.

Aluminum alloy rail crane is a new type of light-duty lifting equipment which mainly applies aluminum alloy walking rails and pulleys, uses carbon steel as structural support or accessories, and combines aluminum alloy and carbon steel. The carrying capacity of aluminum alloy rail crane is from 125kg to 2000kg. The smooth and stable system makes your operation more convenient, more ergonomic, newer, better and smoother. Standard modular accessories make installation and transformation more convenient. The low friction coefficient makes it easier for the aluminum alloy rail crane to handle heavy loads. Nylon wheels and aluminum alloy surfaces are smoother. Standard modular accessories make installation and transformation more convenient. The low friction coefficient makes it easier for the aluminum alloy rail crane to handle heavy loads. Unique combination of nylon wheel and aluminum alloy surface. So that the distance between the lifting points can be larger and the cost can be saved. The ergonomic workstation design of the aluminum alloy rail crane has a direct impact on productivity, so that your production can benefit a lot. It redefines the smooth operation characteristics of the new light-duty crane system, making your lifting more easy.

Aluminum alloy rail crane is a new type of light-duty lifting equipment which mainly applies aluminum alloy walking rails and pulleys, uses carbon steel as structural support or accessories, and combines aluminum alloy and carbon steel. The carrying capacity of aluminum alloy rail crane is from 125kg to 2000kg. The smooth and stable system makes your operation more convenient, more ergonomic, newer, better and smoother. Standard modular accessories make installation and transformation more convenient. The low friction coefficient makes it easier for the aluminum alloy rail crane to handle heavy loads. Nylon wheels and aluminum alloy surfaces are smoother. Standard modular accessories make installation and transformation more convenient. The low friction coefficient makes it easier for the aluminum alloy rail crane to handle heavy loads. Unique combination of nylon wheel and aluminum alloy surface. So that the distance between the lifting points can be larger and the cost can be saved. The ergonomic workstation design of the aluminum alloy rail crane has a direct impact on productivity, so that your production can benefit a lot. It redefines the smooth operation characteristics of the new light-duty crane system, making your lifting more easy.

Aluminum alloy rail crane is a new type of light-duty lifting equipment which mainly applies aluminum alloy walking rails and pulleys, uses carbon steel as structural support or accessories, and combines aluminum alloy and carbon steel. The carrying capacity of aluminum alloy rail crane is from 125kg to 2000kg. The smooth and stable system makes your operation more convenient, more ergonomic, newer, better and smoother. Standard modular accessories make installation and transformation more convenient. The low friction coefficient makes it easier for the aluminum alloy rail crane to handle heavy loads. Nylon wheels and aluminum alloy surfaces are smoother. Standard modular accessories make installation and transformation more convenient. The low friction coefficient makes it easier for the aluminum alloy rail crane to handle heavy loads. Unique combination of nylon wheel and aluminum alloy surface. So that the distance between the lifting points can be larger and the cost can be saved. The ergonomic workstation design of the aluminum alloy rail crane has a direct impact on productivity, so that your production can benefit a lot. It redefines the smooth operation characteristics of the new light-duty crane system, making your lifting more easy.