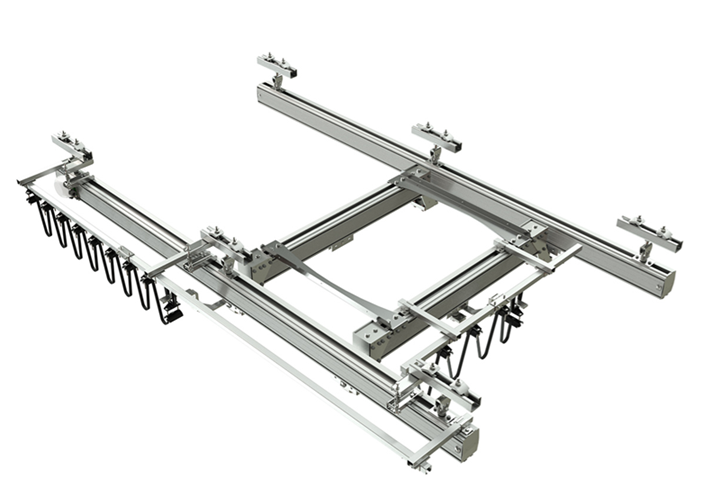

Aluminum alloy modular crane Aluminum alloy kbk rail crane Rigid rail crane

The aluminum alloy kbk crane adopts anodized aluminum profile, and the enclosed track is maintenance-free, has low rolling resistance, and saves effort in dragging.

Advantages at a glance

Ergonomic engineering design principles

The combination of the lightweight aluminum profile and the smoothly running trolley makes manual operation easier than ever. Only a little force can achieve rapid movement and braking, reducing the physical burden of workers.

Outstanding cost-effectiveness

The product realizes the value and benefit of the whole service cycle, and the clever combination with the steel rail expands the distance between the lifting points. At the same time, valuable plant space can be saved.

Flexible control unit

Modular design and application based on the principle of standard parts can realize manual, electric, pneumatic and fully automatic control modes, and can add new original parts or replace existing parts at any time.

Efficient service guarantee

We not only provide you with free pre-sales consultation and program design, but also a team that is ready to serve you at any time, so that you can truly worry-free.

Characteristic description

It adopts anodizing process without painting.

It has light weight and strong load-bearing capacity, which conforms to ergonomics.

The track system runs smoothly, and the drag resistance is less than 0.3%.

Rated load: multiple forms to meet different load and station requirements.

There is no electric welding node to avoid secondary deformation.

The secondary protection device is safer, and the safety factor of the metal components of the hanger is more than 5 times.

Meet the requirements of the crane light-duty industry specification.

Secondary protection device: We recommend that the main beam and hoist trolley be equipped with secondary protection and anti-falling devices as standard.

Modular products, easy to extend and install, and short delivery time.

Advantages at a glance

Ergonomic engineering design principles

The combination of the lightweight aluminum profile and the smoothly running trolley makes manual operation easier than ever. Only a little force can achieve rapid movement and braking, reducing the physical burden of workers.

Outstanding cost-effectiveness

The product realizes the value and benefit of the whole service cycle, and the clever combination with the steel rail expands the distance between the lifting points. At the same time, valuable plant space can be saved.

Flexible control unit

Modular design and application based on the principle of standard parts can realize manual, electric, pneumatic and fully automatic control modes, and can add new original parts or replace existing parts at any time.

Efficient service guarantee

We not only provide you with free pre-sales consultation and program design, but also a team that is ready to serve you at any time, so that you can truly worry-free.

Characteristic description

It adopts anodizing process without painting.

It has light weight and strong load-bearing capacity, which conforms to ergonomics.

The track system runs smoothly, and the drag resistance is less than 0.3%.

Rated load: multiple forms to meet different load and station requirements.

There is no electric welding node to avoid secondary deformation.

The secondary protection device is safer, and the safety factor of the metal components of the hanger is more than 5 times.

Meet the requirements of the crane light-duty industry specification.

Secondary protection device: We recommend that the main beam and hoist trolley be equipped with secondary protection and anti-falling devices as standard.

Modular products, easy to extend and install, and short delivery time.

Advantages at a glance

Ergonomic engineering design principles

The combination of the lightweight aluminum profile and the smoothly running trolley makes manual operation easier than ever. Only a little force can achieve rapid movement and braking, reducing the physical burden of workers.

Outstanding cost-effectiveness

The product realizes the value and benefit of the whole service cycle, and the clever combination with the steel rail expands the distance between the lifting points. At the same time, valuable plant space can be saved.

Flexible control unit

Modular design and application based on the principle of standard parts can realize manual, electric, pneumatic and fully automatic control modes, and can add new original parts or replace existing parts at any time.

Efficient service guarantee

We not only provide you with free pre-sales consultation and program design, but also a team that is ready to serve you at any time, so that you can truly worry-free.

Characteristic description

It adopts anodizing process without painting.

It has light weight and strong load-bearing capacity, which conforms to ergonomics.

The track system runs smoothly, and the drag resistance is less than 0.3%.

Rated load: multiple forms to meet different load and station requirements.

There is no electric welding node to avoid secondary deformation.

The secondary protection device is safer, and the safety factor of the metal components of the hanger is more than 5 times.

Meet the requirements of the crane light-duty industry specification.

Secondary protection device: We recommend that the main beam and hoist trolley be equipped with secondary protection and anti-falling devices as standard.

Modular products, easy to extend and install, and short delivery time.

Advantages at a glance

Ergonomic engineering design principles

The combination of the lightweight aluminum profile and the smoothly running trolley makes manual operation easier than ever. Only a little force can achieve rapid movement and braking, reducing the physical burden of workers.

Outstanding cost-effectiveness

The product realizes the value and benefit of the whole service cycle, and the clever combination with the steel rail expands the distance between the lifting points. At the same time, valuable plant space can be saved.

Flexible control unit

Modular design and application based on the principle of standard parts can realize manual, electric, pneumatic and fully automatic control modes, and can add new original parts or replace existing parts at any time.

Efficient service guarantee

We not only provide you with free pre-sales consultation and program design, but also a team that is ready to serve you at any time, so that you can truly worry-free.

Characteristic description

It adopts anodizing process without painting.

It has light weight and strong load-bearing capacity, which conforms to ergonomics.

The track system runs smoothly, and the drag resistance is less than 0.3%.

Rated load: multiple forms to meet different load and station requirements.

There is no electric welding node to avoid secondary deformation.

The secondary protection device is safer, and the safety factor of the metal components of the hanger is more than 5 times.

Meet the requirements of the crane light-duty industry specification.

Secondary protection device: We recommend that the main beam and hoist trolley be equipped with secondary protection and anti-falling devices as standard.

Modular products, easy to extend and install, and short delivery time.