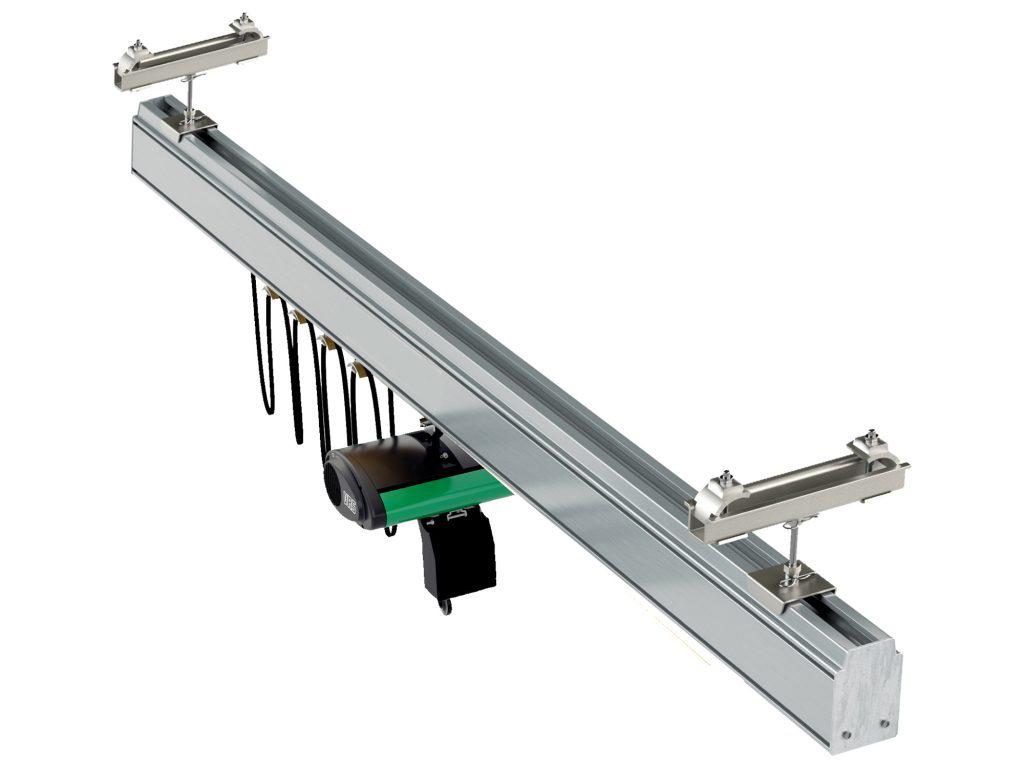

Aluminum Rails for Crane Systems

Aluminum rail is a commonly used material in crane systems. It is lightweight, corrosion-resistant, high-strength and easy to process. The use of aluminum rails in crane systems can reduce the weight of the entire system and improve the operating efficiency and stability of the crane. At the same time, aluminum rails have good electrical conductivity and can be used as conductive rails in electric crane systems to ensure stable power transmission. In addition, aluminum rails also have good surface gloss and decorative properties, which can improve the overall aesthetics of the crane system.

What are the characteristics of aluminum rails used in crane systems:

● It is lighter than traditional steel rails but has higher strength. This makes installation and maintenance easier and reduces the load on the crane structure.

● It has good corrosion resistance and can resist the erosion of humidity, chemicals and other environmental factors. This makes aluminum rails more reliable for use in wet or corrosive environments.

● The surface is smooth and can provide good guiding performance, allowing the crane to operate and position smoothly. This is critical to the accurate operation and safety of the crane.

● It has high wear resistance and can resist friction and wear between crane wheels and rails. This extends the life of the track and reduces the frequency of maintenance and replacement.

● It has good electrical insulation properties and can reduce current conduction and interference. This is very important for crane systems with special requirements, such as electrical isolation and anti-static.

● Can be customized according to the needs of the crane system. It can be designed and manufactured according to requirements such as track length, shape and connection method to adapt to different crane applications.

The operating principle of light crane on aluminum rails:

● Track installation: First, aluminum rails need to be properly installed on the ground or other supporting structure. The installation of the track should ensure that it is flat, level and consistent with the design requirements of the crane.

● Wheel-rail fit: Light cranes often use multiple wheel-rail fits with aluminum rails to operate. These wheel rails are mounted on the base of the crane or other moving parts. The fit between the wheel rail and the aluminum rail should be tight and smooth to ensure the stable operation of the crane.

● Guidance and positioning: The smooth guiding properties of aluminum rails enable the crane to be accurately guided and positioned on the rails. The crane's wheel-rail system ensures that the crane maintains the correct direction and position on the track through contact with the aluminum rails.

● Load transfer: The crane transfers the weight of the load to the rails through contact between the wheel rails and the aluminum rails. The friction between the wheel rails and the aluminum rails and the stability of the support structure jointly bear the role of the crane load.

● Movement and operation: Light cranes enable the transportation and operation of loads by moving on aluminum rails. Movement of the crane can be achieved by manual push, electric drive or other means, depending on the design and functionality of the crane.