Routine maintenance method of aluminum alloy track

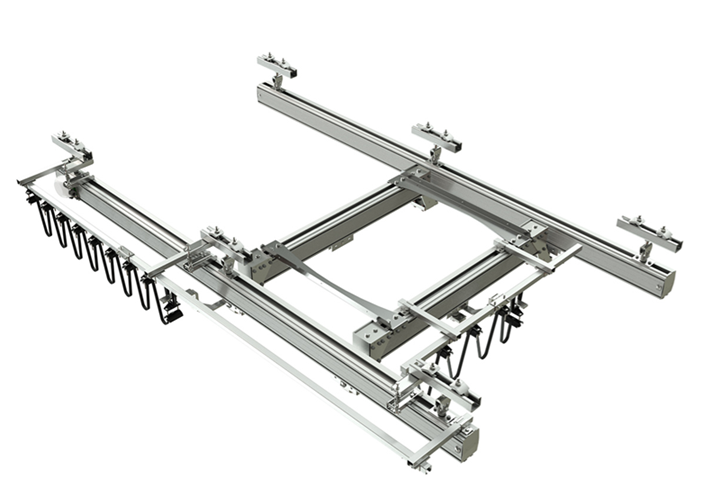

Aluminum alloy track is a commonly used lifting equipment in large-scale product workshops such as cars and shipbuilding. It can easily transport heavy objects from one place to another. It is a kind of equipment for lifting heavy objects in the air. The track of the track is installed on the ceiling, and the lifting of heavy objects relies on the electric hoist equipment stuck in the track. However, the quality of the track is required to be good, otherwise it may cause accidents. In addition, the routine maintenance of the track shall be well done. The specific methods are as follows:

1. Strictly prevent "deviance": the track is only widely used, and one of its important functions is to avoid the occurrence of "deviance". Only by using this track to restrict the operation of the lifting trolley within a certain track scale can it ensure that the operation of the lifting equipment is within a controllable scale. Therefore, when using the track, we must pay attention to regular inspection, so as to prevent trouble and make the work solid and practical. Only when the problems are found and solved in time can the "derailment" of the lifting trolley be avoided.

2. Good lubrication: the wear rate of the track track is often very high because it takes on life for a long time. Therefore, the key to maintenance is to reduce its wear and tear, which requires good lubrication. Too much lubrication will make the trolley slip, but if the lubrication is insufficient, the trolley will rub the track excessively, which will aggravate the damage of the track. Therefore, it is necessary to seriously and equivalently lubricate the track, so as to ensure that the track can be well maintained.

3. Reduce "overdraft": no matter how good the lifting equipment is, it has a certain period of use, and it is even easier for the equipment working under overload. The same is true for the track. Although there is a certain space reserved in the bearing weight of the track, attention must be paid not to "eat" it during the use. Only by strictly following the operating standards and reducing overdraft can we make the track live longer and use more awesome.