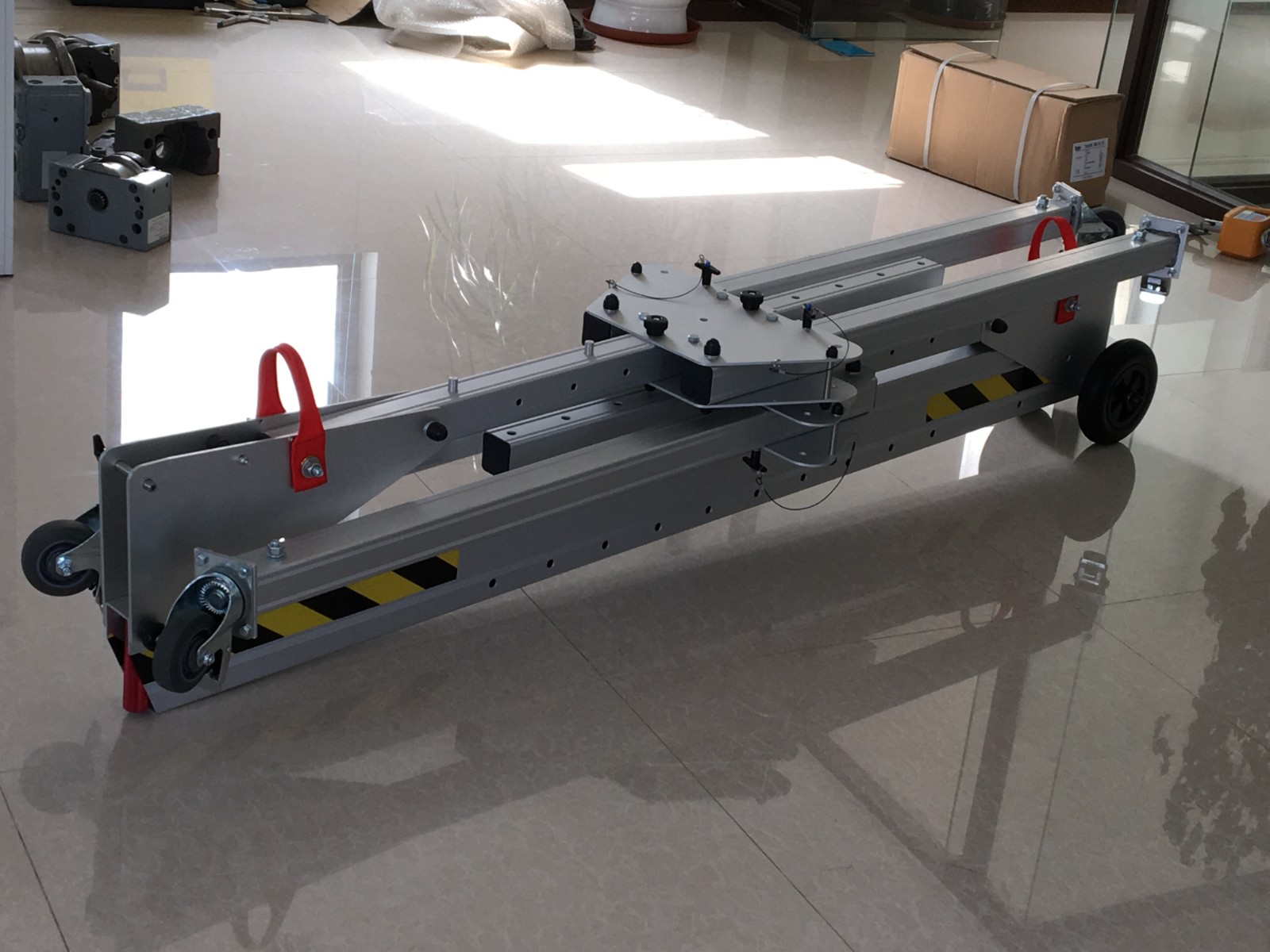

Aluminum Fixed Height Gantry Crane

Fixed height gantry crane is an important piece of equipment widely used in industries, docks, logistics centers and other large cargo handling sites. Its name comes from its unique structure, in which two vertical legs, or struts, support beams, creating a doorway-like shape. With an electric or hydraulic drive system, the gantry crane can move along the beam for lifting and handling cargo at different locations.

Reasons for choosing aluminum materials

● Aluminum alloy has the characteristics of low density and light weight, which greatly reduces the overall weight of the aluminum gantry crane and facilitates transportation and installation.

● A dense oxide film is formed on the surface of the aluminum alloy, which has good corrosion resistance and can adapt to harsh working environments.

● The surface of the aluminum alloy has been anodized, spray-coated, etc., giving it a beautiful appearance and improving the overall grade of the equipment.

● Aluminum alloy materials have high strength and stiffness, making aluminum gantry cranes have good durability and can maintain stable performance for a long time.

Structure and composition

● The gantry is the main structure of the aluminum gantry crane, which is composed of aluminum alloy columns and beams. Columns usually adopt rectangular or circular cross-sections and have good bending and torsion resistance. The cross beam connects the two columns and bears the horizontal force generated by the lifting mechanism.

● The lifting mechanism includes electric hoists, wire ropes, pulleys and other components. The electric hoist is the power source that drives the wire rope to lift and lower. It is usually driven by electric or hydraulic power. The steel wire rope is responsible for connecting the electric hoist and the heavy object and withstanding the tensile force during the hoisting process. The pulley is installed on the gantry to change the movement direction of the wire rope and realize the lifting and transportation of heavy objects.

● The electrical control system is the brain of the aluminum gantry crane and is responsible for controlling the movement and operation of the lifting mechanism. It usually consists of a control cabinet, operating console, sensors and other components, and can realize automated and intelligent hoisting operations.

Advantages of aluminum gantry crane

● The compact design and lightweight structure make it highly flexible.

● It has good corrosion resistance and is not easy to rust and damage, so the maintenance cost is relatively low.

● The lifting and handling tasks of goods can be completed quickly and accurately, greatly improving work efficiency.

● Hoisting operations can be performed at different locations to adapt to different work needs.