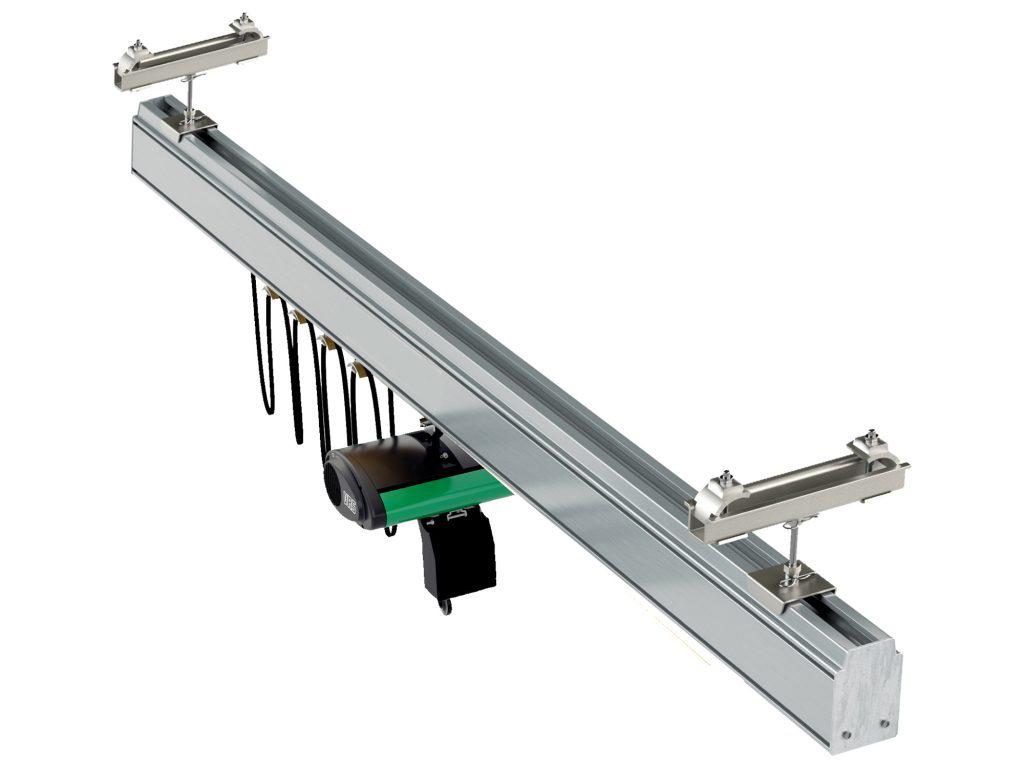

Flexible Aluminum Alloy Rail Crane

Flexible aluminum alloy rail crane is an advanced lifting equipment, mainly composed of track, suspension device, trolley, lifting device and some functional components. Its emergence has brought higher efficiency and safety to industrial production.

The Main Structural Components

Rail

Rail is the operation basis of the crane, which is divided into linear rail and curved rail. The aluminum alloy material is selected due to good corrosion resistance and adaptability, which can meet different working environments and requirements.

Suspension Device

The suspension device is usually mounted on the lower edge of an I-beam or H-beam, or on a concrete beam.

Trolley

Trolley is mounted inside the rail, which can be moved in the X - and Y-axis directions. According to the needs of use, it is divided into manual and electric types, providing more options for operation.

Hoist Lifting Device

The hoist lifting device is usually employed with chain electric hoist, pneumatic balancer or intelligent balancing hoist, etc., which is used in conjunction with the hoist to complete lifting and lowering operations.

Functional Unit

Functional unit includes main beam, auxiliary beam, track connecting plate, stop, end cover, etc. to assist the main track in supporting, connecting, limiting and other functions to ensure the integrity and stability of the crane system.

Advantages and Characteristics

• Lightweight design: Aluminum alloy rail crane is made of aluminum alloy material. Compared to traditional lifting equipment, which is lighter and easier to install and handling.

• High Strength: Although lightweight, aluminum alloy rail cranes have high strength and can withstand large weights.

• Corrosion Resistance: Aluminum alloy materials show good corrosion resistance in harsh working environments, extending the service life of the equipment.

• Modular standard design: The whole system is easy to install and maintain, which greatly improves the work efficiency.

Solve the Problem

Due to aluminum alloy rail crane compact structure, it can carry out efficient lifting operations in a limited space, improving the space utilization rate.

Work Efficiency Problem

Aluminum alloy rail crane runs smoothly and operates flexibly, which can complete lifting tasks quickly and accurately, and improves work efficiency.

Security Issue

It has good stability and reliability, reduces the possibility of accidents and ensures the safety of staff.

In short, aluminum alloy rail crane with its unique structure and advantages, has been widely used in many industrial fields such as clean workshop, automobile production line, food and electronics industry. It not only improves production efficiency, but also ensures work safety, and is an indispensable and efficient handling tool in the industrial field.