Application of Aluminum Gantry Crane in Clean Room

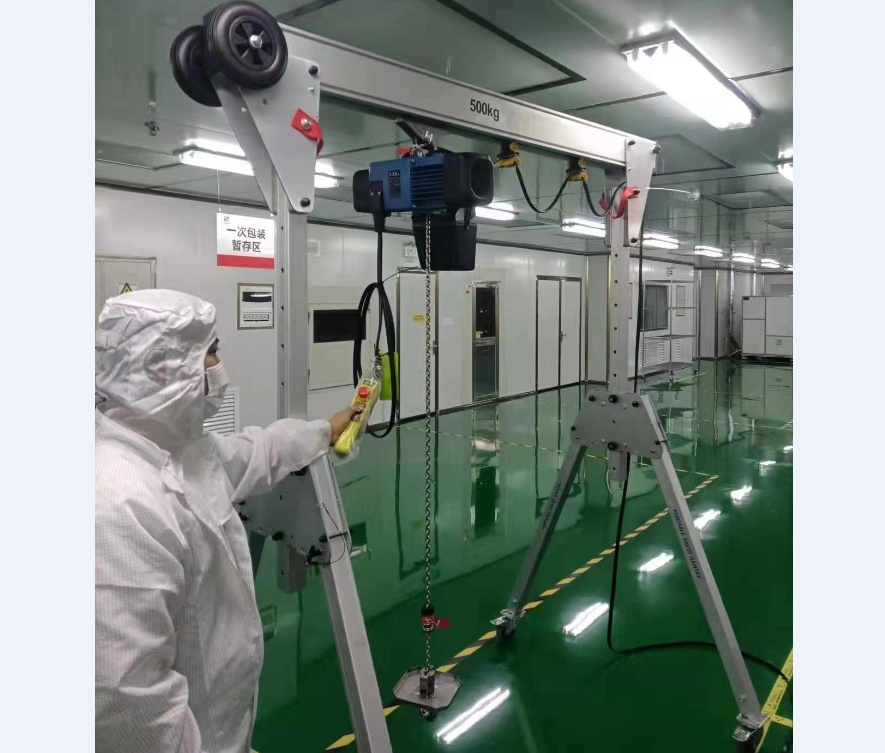

In modern industrial production environments, clean rooms, as a specific area with strict requirements for air cleanliness, are increasingly used in high-precision industries such as semiconductor manufacturing, pharmaceutical production, and food processing. In such an environment, lifting equipment is a key tool for material handling, and its performance and quality are directly related to production efficiency and product quality. Aluminum gantry cranes play an irreplaceable role in clean rooms with their unique advantages. As a lightweight and high-strength metal material, aluminum alloy has excellent corrosion resistance, electrical conductivity and thermal conductivity. At the same time, its surface is easy to clean and does not easily adhere to dust and bacteria. These characteristics make aluminum gantry cranes uniquely advantageous in clean rooms.

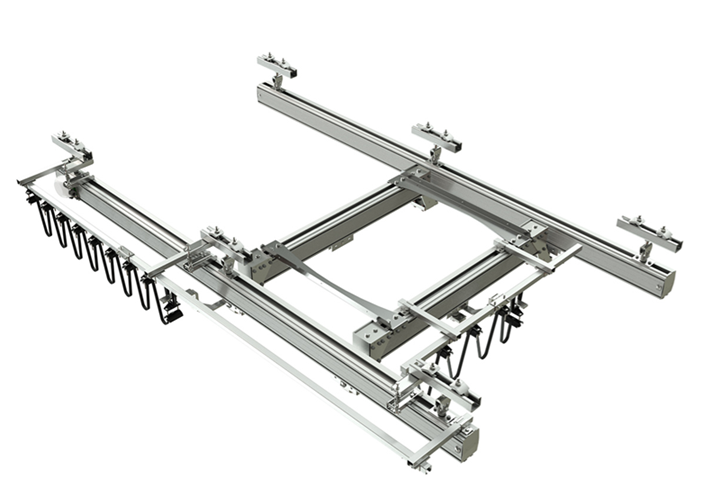

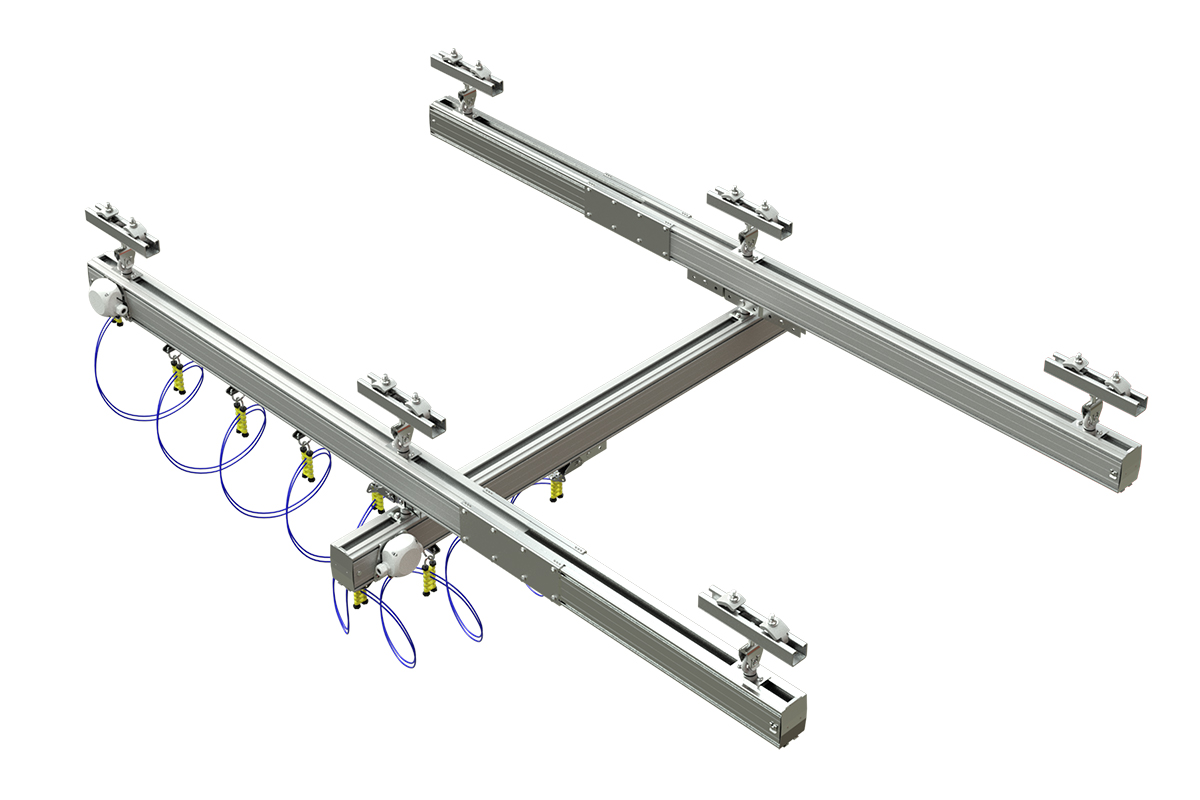

Compared with traditional steel gantry cranes, aluminum gantry cranes are lighter in weight, which greatly reduces labor costs and time costs during transportation and installation. At the same time, the lightweight characteristics also make the aluminum gantry crane more stable during operation and reduce dust generated by vibration. The high strength of the aluminum gantry crane ensures its stability and safety when carrying heavy objects. Although aluminum alloys have a lower density, they are strong and stiff enough to meet the needs of most lifting operations. In addition, the aluminum gantry crane has a reasonable structural design, which can effectively disperse the load and reduce stress concentration, thus improving the service life and safety of the equipment.

The cleanliness of the aluminum gantry crane meets the requirements of clean rooms. The surface of aluminum alloy is smooth and difficult to adhere to dust and bacteria, which allows the aluminum gantry crane to maintain a high degree of cleanliness when operating in a clean room. At the same time, the maintenance of aluminum gantry cranes is relatively simple. You only need to clean the surface regularly to maintain its good operating condition.

In clean rooms, aluminum gantry cranes have a wide range of applications. It can be used to transport equipment, parts, raw materials, etc., providing efficient and reliable logistics support for the clean room production process. For example, in the semiconductor manufacturing process, aluminum gantry cranes can be used to transport precision equipment such as wafers and photolithography machines to ensure the smooth progress of the production process. In pharmaceutical production, aluminum gantry cranes can be used to transport raw materials, intermediates and other materials to ensure the quality and safety of pharmaceutical production.

The application of aluminum gantry cranes in clean rooms also requires attention to some issues. First of all, aluminum gantry cranes need to be cleaned and maintained regularly to ensure that their surfaces are always clean. Secondly, when selecting an aluminum gantry crane, it needs to be customized according to the actual conditions and operational needs of the clean room to ensure that the performance and specifications of the equipment meet actual needs. Finally, when using aluminum gantry cranes, operating procedures need to be followed to ensure the safe operation of the equipment.