Get A KBK Lightweight Modular Crane for Your Industry

In modern industrial production, material handling is a crucial work link. In order to improve work efficiency, ensure safety and meet the diverse needs, the KBK lightweight crane came into being. It has become a popular suspension system for many enterprises because of its unique characteristics of remodeling and expansion.

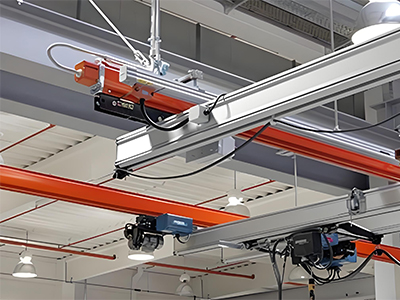

KBK standard Component Parsing

Suspended Rail

The suspension rail is an important part of the KBK crane. Its material is strong and well designed to withstand large weights. Suspension tracks of different lengths and specifications provide the basis for flexible configuration of the system.

For example, in some workshops with limited space, a shorter suspension track can be selected to ensure the normal operation of the crane and not take up too much space; In large plants, longer suspension tracks can be used to achieve a wider range of material handling.

Electric Hoist

Electric hoist plays a key role in material handling. It has different lifting capacity and running speed, and can be selected according to the actual handling needs.

For lighter goods, electric hoists with smaller lifting capacity but faster running speed can be selected to improve handling efficiency; For heavier goods, it is necessary to be equipped with a stronger lifting capacity of the electric hoist, to ensure the safety and stability of the lifting.

Bracket

The bracket supports and fixes the entire suspension system. Its stable structure ensures that the system does not wobble or tilt during operation.

Depending on the installation environment, bracket can be customized to suit different ceiling heights and floor conditions.

Adapting Piece

Connectors are the key components that hold each component tightly together. Quality connectors ensure the integrity and stability of the system.They are carefully designed and manufactured to withstand the various stresses and pulls that occur when the system is in operation.

Remodelable Features and Application Examples

System Adjustment

The flexible KBK crane can adjust the system in time according to the change of the actual working scene. For example, when the production process changes and the material handling path needs to be re-planned, it can be achieved by adjusting the layout of the suspension rail. Assuming that there are obstacles in the original handling route, the obstacles can be bypassed through reconstruction to make the handling work more smooth.

Exchange Assemblies

According to the characteristics of the cargo and the change of handling requirements, the replacement of the components can always keep the crane in good working condition. For example, when the size of the goods increases and the length of the original suspension track is insufficient, a longer track can be replaced; When the weight of the transported goods exceeds the carrying capacity of the original electric hoist, it is necessary to replace the electric hoist with a stronger lifting capacity.

Extendable Features and Application Examples

Add Component

On the basis of the original system, additional suspension rails, brackets and other components can be added to improve the handling capacity and range of the system.

For example, the expansion of the production scale of the enterprise, the need to carry more goods, at this time to increase the suspension rail and bracket, to meet the new material handling needs.

Function Expansion

By adding an automatic control system, the automatic operation of material handling is realized, and the work efficiency and accuracy are improved.

For example, the introduction of intelligent sensors and control systems enables the boom crane to automatically identify the position and weight of the cargo for precise lifting operations.

The flexible KBK crane provides great flexibility and reliability for industrial material handling thanks to its reconfigurable and extendable features. Through the reasonable configuration of KBK standard components, enterprises can adjust and optimize the suspension system at any time according to their own development and changes, thereby improving production efficiency and reducing operating costs.