Introduction of KBK Aluminum Alloy Rail Crane

KBK aluminum alloy rail crane is a kind of light suspension lifting equipment, which is widely used in industrial production lines, assembly lines, warehouses and other places for the handling, assembly and stacking of materials. The KBK system is a modular lightweight suspended lifting equipment that can be quickly assembled and installed according to needs. It is very suitable for workplaces that require frequent handling and assembly.

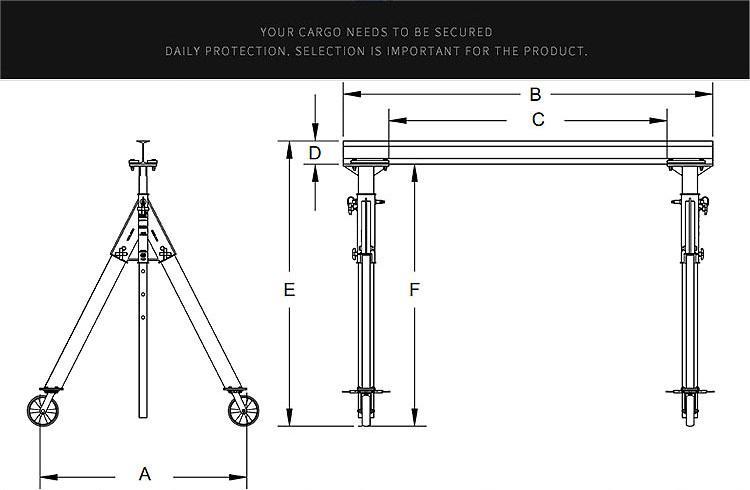

KBK aluminum alloy track crane is mainly composed of track, electric hoist, pulley block, bracket and other accessories. Among them, the track is the main load-bearing structure of the crane. It is usually made of high-strength aluminum alloy material and has the advantages of light weight, high strength and corrosion resistance. The electric hoist is the main lifting device of the crane. It uses a motor to drive a chain or wire rope to lift objects. The pulley block is used to change the direction of the wire rope so that the object can be moved to different positions as needed. The bracket is the component that connects the track and the electric hoist and plays a supporting and fixing role. Other accessories include limit switches, buffers, anti-collision devices, etc. to protect equipment and personnel.

Product advantages:

1. The track is made of high-strength aluminum alloy material. Compared with traditional steel track crane, it is lighter and easier to handle and move.

2. It has high strength and rigidity and can withstand large loads and impact forces, making the crane more stable and reliable during operation.

3. It has good corrosion resistance and can adapt to various complex environmental conditions and extend the service life of the equipment.

4. Using an electric hoist as the lifting device has lower energy consumption and less impact on the environment than traditional large diesel or hydraulic cranes.

5. The structure is relatively simple and the connections between the components are compact, making the maintenance and upkeep of the equipment easier.

Scenes to be used:

1. Production line handling: Used for material handling on the production line, which can quickly and accurately complete the lifting and movement of materials and improve production efficiency.

2. Warehouse shelf handling: used for handling and adjusting warehouse shelves to facilitate the access and management of goods.

3. Logistics loading and unloading: used for the loading, unloading and transportation of goods, especially in scenarios such as container loading and unloading and vehicle loading and unloading.

4. Large equipment installation: used for the installation and disassembly of large equipment, such as generator sets, pipeline hoisting, etc.

5. Application in special environments: In some special environments, such as high temperature, low temperature, strong magnetic field, radioactivity, etc., KBK aluminum alloy track crane has certain application advantages due to its light weight, corrosion resistance and other advantages.