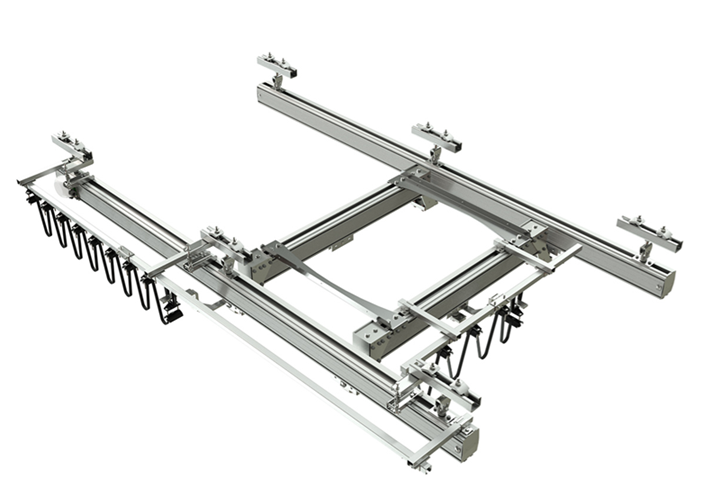

Aluminum alloy KBK rail crane

The aluminum alloy rail lifting system is currently a relatively labor-saving lifting system. The whole system includes aluminum alloy slide rails + aluminum alloy rail accessories + lifting tools, which are widely used in welding workshops, assembly workshops, and auto parts production plants in the automotive industry. Electromechanical industry, packaging industry, home appliance industry, sanitary ware industry and other industries.

Aluminum alloy track specifications:

1. The lengths are 1m, 2m, 3m, 4m, 5m, 6m, which can be selected according to needs;

2. Load specifications: 40kg, 125kg, 500kg, 1 ton, 1.8 ton, can be selected according to needs

Introduction to the types of supporting lifting tools:

Aluminum alloy track system, equivalent to suspension translation device, can be matched with lifting tools such as pneumatic hoist, pneumatic balancer, spring balancer, etc., forming a whole material suspension transportation system, reducing labor intensity and improving work efficiency. Our aluminum alloy kbk rail crane can customize a more suitable rail lifting scheme according to the actual working environment and load requirements.

Aluminum alloy KBK compared with ordinary KBK:

1. Aluminum alloy KBK: The track is a high-quality and high-strength aluminum alloy profile, which is lighter than ordinary KBK, which greatly reduces the load of the suspension beam. At the same time, it is more labor-saving for workers to pull the KBK pulley during operation. To a certain extent, Effort less means higher work efficiency.

2. Compared with ordinary KBK, it is more beautiful. Due to the characteristics of the aluminum alloy itself, it will not rust, so there is no need for baking paint on the KBK track, and the surface is bright and silver, which is easier to integrate with the ambient color of the workshop.

3. Due to its own advantages, aluminum alloy KBK has the tendency to gradually replace the traditional steel KBK. At present, many workshops in the automotive, machining, chemical and other industries have begun to use aluminum alloy KBK to replace steel KBK.

Aluminum alloy track specifications:

1. The lengths are 1m, 2m, 3m, 4m, 5m, 6m, which can be selected according to needs;

2. Load specifications: 40kg, 125kg, 500kg, 1 ton, 1.8 ton, can be selected according to needs

Introduction to the types of supporting lifting tools:

Aluminum alloy track system, equivalent to suspension translation device, can be matched with lifting tools such as pneumatic hoist, pneumatic balancer, spring balancer, etc., forming a whole material suspension transportation system, reducing labor intensity and improving work efficiency. Our aluminum alloy kbk rail crane can customize a more suitable rail lifting scheme according to the actual working environment and load requirements.

Aluminum alloy KBK compared with ordinary KBK:

1. Aluminum alloy KBK: The track is a high-quality and high-strength aluminum alloy profile, which is lighter than ordinary KBK, which greatly reduces the load of the suspension beam. At the same time, it is more labor-saving for workers to pull the KBK pulley during operation. To a certain extent, Effort less means higher work efficiency.

2. Compared with ordinary KBK, it is more beautiful. Due to the characteristics of the aluminum alloy itself, it will not rust, so there is no need for baking paint on the KBK track, and the surface is bright and silver, which is easier to integrate with the ambient color of the workshop.

3. Due to its own advantages, aluminum alloy KBK has the tendency to gradually replace the traditional steel KBK. At present, many workshops in the automotive, machining, chemical and other industries have begun to use aluminum alloy KBK to replace steel KBK.

Aluminum alloy track specifications:

1. The lengths are 1m, 2m, 3m, 4m, 5m, 6m, which can be selected according to needs;

2. Load specifications: 40kg, 125kg, 500kg, 1 ton, 1.8 ton, can be selected according to needs

Introduction to the types of supporting lifting tools:

Aluminum alloy track system, equivalent to suspension translation device, can be matched with lifting tools such as pneumatic hoist, pneumatic balancer, spring balancer, etc., forming a whole material suspension transportation system, reducing labor intensity and improving work efficiency. Our aluminum alloy kbk rail crane can customize a more suitable rail lifting scheme according to the actual working environment and load requirements.

Aluminum alloy KBK compared with ordinary KBK:

1. Aluminum alloy KBK: The track is a high-quality and high-strength aluminum alloy profile, which is lighter than ordinary KBK, which greatly reduces the load of the suspension beam. At the same time, it is more labor-saving for workers to pull the KBK pulley during operation. To a certain extent, Effort less means higher work efficiency.

2. Compared with ordinary KBK, it is more beautiful. Due to the characteristics of the aluminum alloy itself, it will not rust, so there is no need for baking paint on the KBK track, and the surface is bright and silver, which is easier to integrate with the ambient color of the workshop.

3. Due to its own advantages, aluminum alloy KBK has the tendency to gradually replace the traditional steel KBK. At present, many workshops in the automotive, machining, chemical and other industries have begun to use aluminum alloy KBK to replace steel KBK.

Aluminum alloy track specifications:

1. The lengths are 1m, 2m, 3m, 4m, 5m, 6m, which can be selected according to needs;

2. Load specifications: 40kg, 125kg, 500kg, 1 ton, 1.8 ton, can be selected according to needs

Introduction to the types of supporting lifting tools:

Aluminum alloy track system, equivalent to suspension translation device, can be matched with lifting tools such as pneumatic hoist, pneumatic balancer, spring balancer, etc., forming a whole material suspension transportation system, reducing labor intensity and improving work efficiency. Our aluminum alloy kbk rail crane can customize a more suitable rail lifting scheme according to the actual working environment and load requirements.

Aluminum alloy KBK compared with ordinary KBK:

1. Aluminum alloy KBK: The track is a high-quality and high-strength aluminum alloy profile, which is lighter than ordinary KBK, which greatly reduces the load of the suspension beam. At the same time, it is more labor-saving for workers to pull the KBK pulley during operation. To a certain extent, Effort less means higher work efficiency.

2. Compared with ordinary KBK, it is more beautiful. Due to the characteristics of the aluminum alloy itself, it will not rust, so there is no need for baking paint on the KBK track, and the surface is bright and silver, which is easier to integrate with the ambient color of the workshop.

3. Due to its own advantages, aluminum alloy KBK has the tendency to gradually replace the traditional steel KBK. At present, many workshops in the automotive, machining, chemical and other industries have begun to use aluminum alloy KBK to replace steel KBK.