How to Install Aluminum Monorail Suspension Crane

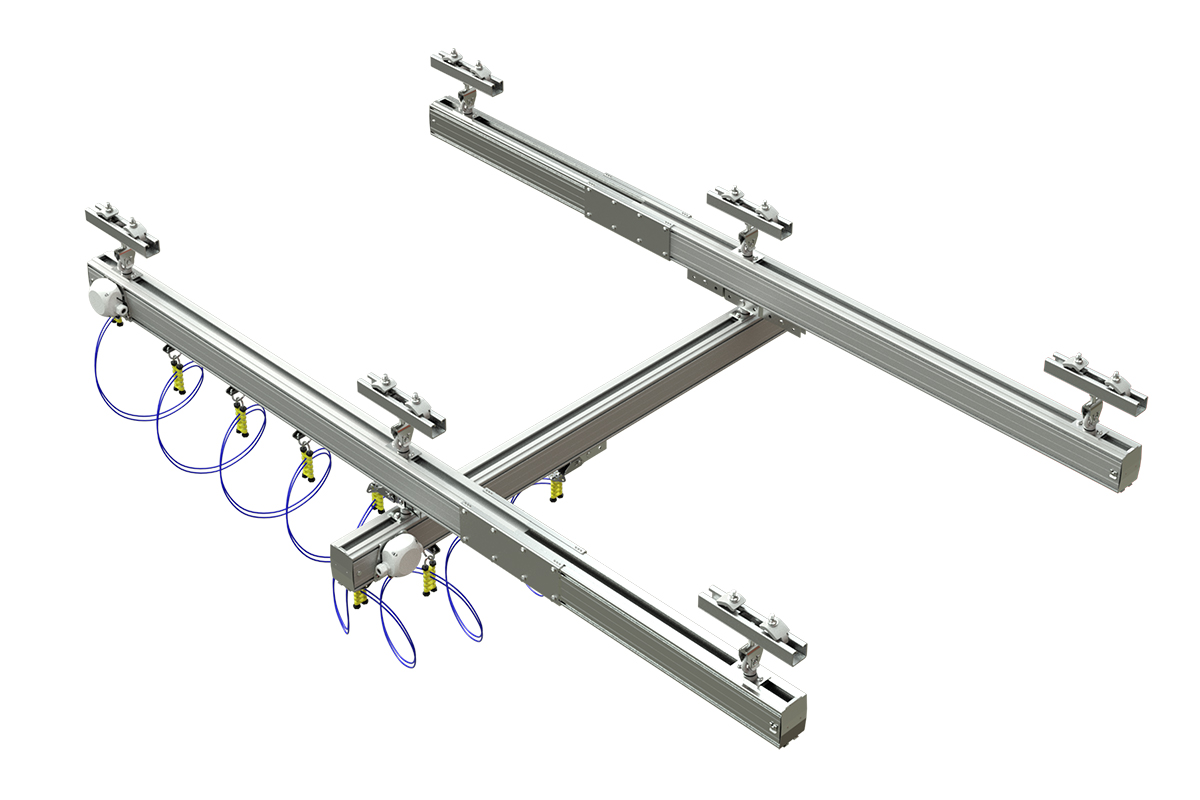

The aluminum monorail suspension crane is a lifting equipment that combines the lightweight and high-strength characteristics of aluminum alloy materials with monorail suspension technology. It hangs heavy objects on the aluminum alloy track through an electric hoist or other lifting mechanism, and moves it horizontally or vertically along the track to meet the material handling needs in industrial production, warehousing and logistics and other fields.

Main feature

● Made of aluminum alloy material, it is lighter in weight than traditional steel cranes, which greatly reduces the burden on the building structure.

● It supports multi-point suspension and multi-stage operation, and can adapt to various material handling needs.

● It is arranged on the ceiling or bracket and does not occupy floor space. It is especially suitable for factories, warehouses, production lines and other places with limited space.

● Equipped with an efficient electric hoist, it can achieve fast and precise material handling and loading and unloading operations, improving work efficiency.

● Low maintenance costs and easy maintenance and repair reduce long-term operating costs.

Installation steps of aluminum monorail suspension crane

Construction preparation:

● Develop detailed construction plans, including project planning, layout design, material procurement, etc.

● Conduct a survey of the construction site to determine the lifting location, installation foundation and other conditions, and perform preprocessing.

Track installation:

● Mark the axis of the crane rail at the installation location, measure and calibrate it.

● According to the axis of the hanging rail, the hanging rail is installed on the installation basis, including fixing bolts, welding and other operations.

● After the installation is completed, debug the track and check the levelness of the track, the firmness of the connection, etc.

Lifting equipment installation:

● Installation of monorail hangers, including fixing hangers, installing driving devices, etc.

● Install the electric hoist, debug and test it to ensure the normal operation of the lifting equipment.

Comprehensive acceptance:

● Conduct quality control on the installation process, including process flow, material selection, welding quality, etc.

● Carry out operation tests to test the stability of the hanging rails, the working condition of the hangers, etc.

● After the installation is completed, a comprehensive inspection will be carried out to ensure that the installation quality and working performance of the aluminum monorail suspension crane meet the requirements.

The above installation steps are only general guidance, and the specific installation process should be adjusted according to the equipment instructions and actual site conditions. During the installation process, safety operating procedures should be strictly followed to ensure construction safety. At the same time, it is recommended that professionals perform installation and debugging work to ensure the normal operation and service life of the equipment. KFCS CRANE has a professional installation service team that can provide customers with remote guidance and on-site installation and debugging. Welcome to contact us to get a quote!