Structural Features and Application of Combined KBK Crane

Combined kbk crane has become a high-profile star product in the market with its unique design and performance. This article will introduce in detail the structural characteristics of kbk cranes and the application scope of kbk light cranes.

Introduction

The combined KBK crane, the European standard single-girder crane, is a lifting equipment widely used in the industrial field. Compared with traditional cranes, kbk light cranes have the advantages of simple structure, convenient operation, and stable operation, so they have been widely used in modern industrial production.

Features

Structural features

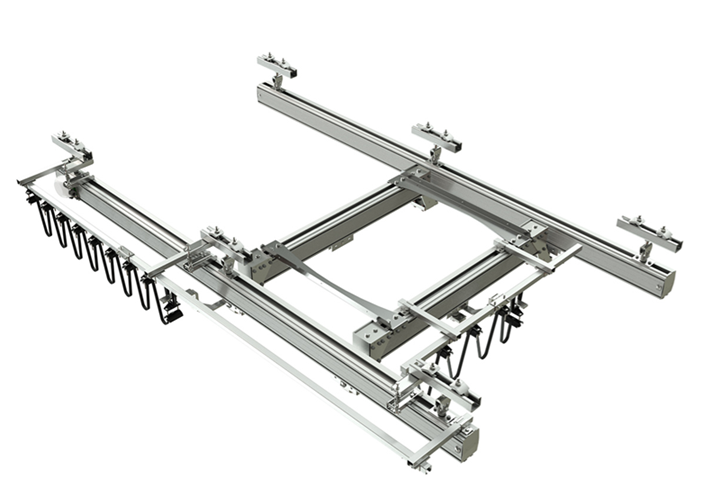

The structure of the combined kbk crane is mainly composed of main beam, end beam, hoist trolley, electric hoist, etc. The main beam is made of high-strength steel, which has stronger overall rigidity and can withstand greater loads. The end beam adopts a closed structure, which has higher stability. The design of the hoist trolley and electric hoist makes the crane operation more flexible and greatly improves work efficiency.

Material Characteristics

The main components of the combined kbk crane are made of high-strength steel. After special processing, they have high strength and toughness and can meet the needs of various complex working conditions. At the same time, due to the adoption of advanced anti-corrosion technology, the corrosion resistance of kbk light cranes has also been significantly improved.

Technological Characteristics

In terms of manufacturing technology, kbk cranes adopt advanced welding technology and precision processing technology to ensure the accuracy and stability of the crane. In addition, the combined kbk crane also adopts an intelligent control system, which can achieve precise control and real-time monitoring, greatly improving the safety and convenience of operation.

Application Scope

Industrial Field

In the industrial field, kbk cranes are widely used in machinery manufacturing, automobile manufacturing, power industry, chemical industry and other fields. With its high efficiency, stability and flexibility, it helps enterprises improve production efficiency and reduce production costs. For example, in the automobile manufacturing industry, combined KBK cranes are used for the lifting and transfer of parts, as well as the assembly process of complete vehicles.

Material Handling

In the manufacturing industry, material handling is an important link. KBK cranes are widely used in various material handling situations, such as warehouses, docks, workshops, etc. By using kbk light cranes, companies can efficiently store, transport, and load materials, thereby improving production efficiency.

Assembly Line

In the assembly line, the combined kbk crane also plays an important role. It can accurately place parts and tools into workers' hands, making the assembly process smoother, reducing workers' labor intensity and improving production efficiency.

Logistics Industry

In the logistics industry, KBK cranes are mainly used for the transportation, loading and unloading of goods. Using KBK cranes can improve work efficiency, reduce labor costs, and ensure the safety and integrity of goods.

Combined KBK cranes are widely used in industrial fields and material handling situations due to their simple structure, convenient operation, and stable operation. In the future, with the continuous development of Industry 4.0 and intelligent manufacturing, kbk light cranes will be more intelligent, efficient and green, providing enterprises with better services.